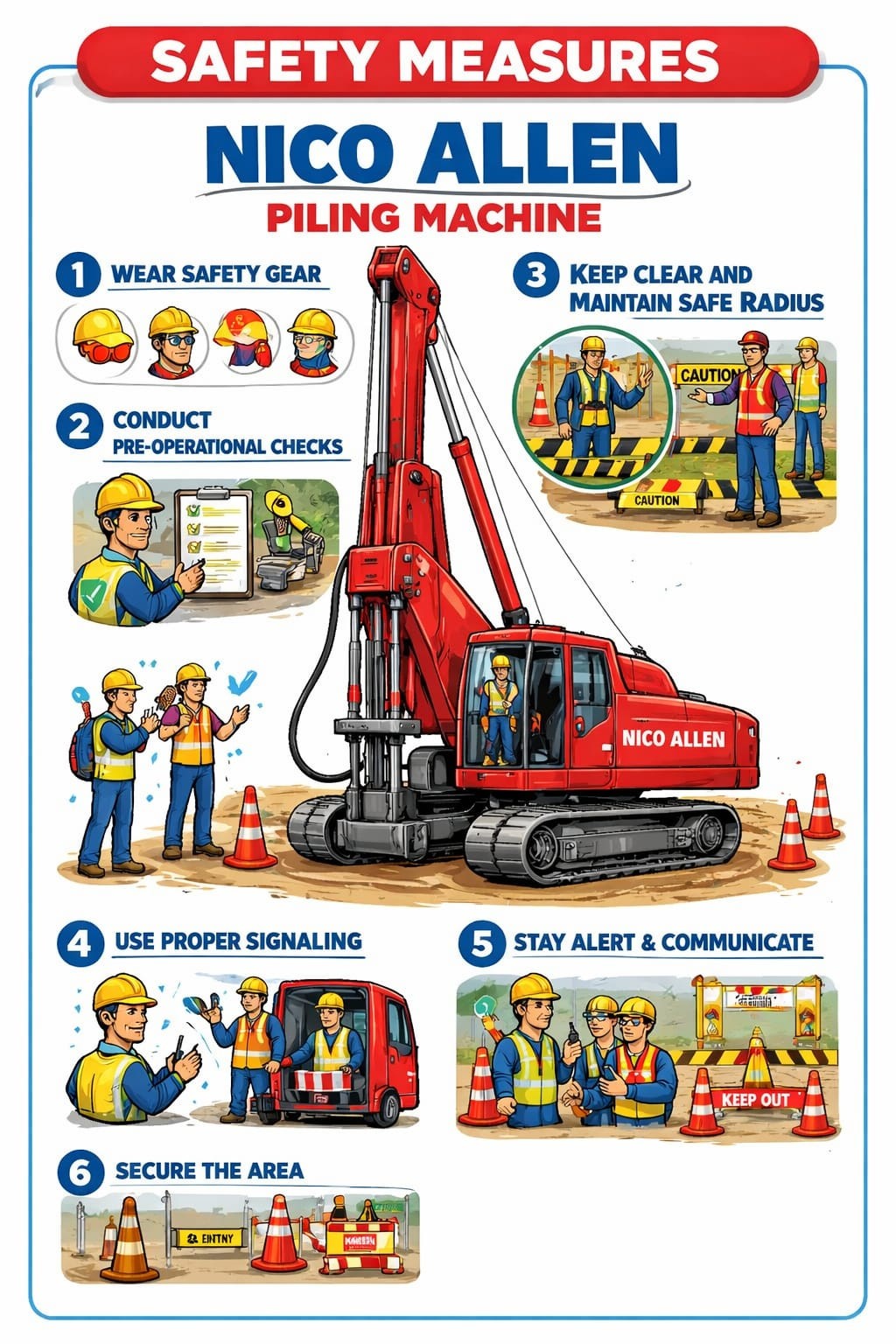

At Nico Allen Infrastructure, safety is the foundation of our operations. As a responsible organization in the construction and infrastructure industry, we are committed to implementing best-in-class construction safety measures and infrastructure safety guidelines across all our projects. Our objective is to protect our workforce, ensure regulatory compliance, and deliver projects safely and efficiently.

A Strong Commitment to Workplace Safety

We prioritize workplace safety in construction by embedding safety into every stage of project planning and execution. Through structured construction risk management, hazard identification, and continuous supervision, we aim to eliminate unsafe conditions and promote a proactive safety culture.

Planning & Risk Assessment

Comprehensive risk identification and mitigation planning before project commencement

Safety Culture

Proactive safety mindset embedded across all organizational levels

Continuous Supervision

24/7 monitoring and supervision of all safety protocols

Personal Protective Equipment (PPE) Compliance

The use of PPE in construction is mandatory at all Nico Allen Infrastructure sites. Employees and visitors are required to wear safety helmets, safety shoes, high-visibility jackets, gloves, goggles, and safety harnesses for elevated work. These practices are essential for accident prevention in construction and maintaining a safe work environment.

Safety Helmets

Mandatory head protection for all site personnel

Safety Shoes

Steel-toe footwear for foot protection

Hi-Vis Jackets

High visibility clothing for all workers

Safety Goggles

Eye protection for hazardous operations

Industrial Gloves

Hand protection for various work activities

Safety Harnesses

Fall protection for elevated work

Zero Tolerance Policy

Nico Allen Infrastructure maintains a strict zero-tolerance policy for PPE violations. All personnel must comply with PPE requirements without exception.

Construction Site Safety Rules and Controls

All project locations strictly follow established construction site safety rules. Sites are secured with barricades, safety signage, and controlled access points. Regular housekeeping inspections are conducted as part of our worksite safety management system to prevent slips, trips, and falls.

Machinery, Equipment, and Operational Safety

In line with civil construction safety practices, all machinery and equipment undergo scheduled inspections and preventive maintenance. Only trained and authorized personnel are permitted to operate equipment, ensuring robust machinery and equipment safety and minimizing operational risks.

Work at Height and Excavation Safety Measures

High-risk activities such as working at height and excavation are managed with strict controls. Work at height safety measures include certified scaffolding, guardrails, safety nets, and lifeline systems. Excavation areas are properly shored, barricaded, and monitored in compliance with industrial safety measures.

Height Work Safety

- Certified scaffolding systems

- Guardrails and safety nets

- Lifeline and harness systems

- Competent personnel only

Excavation Safety

- Proper shoring and bracing

- Barricaded excavation areas

- Regular soil testing

- Continuous monitoring

Fire, Electrical, and Hazard Control

We enforce stringent fire and electrical safety in construction by providing fire-fighting equipment, proper electrical grounding, insulated tools, and safe wiring practices. Hot work activities are carried out only after risk assessment and approval to ensure full safety compliance.

Fire Safety Equipment

Fire extinguishers, hydrants, and alarms at strategic locations

Electrical Safety

Proper grounding, insulated tools, and safe wiring practices

Hot Work Permits

Mandatory permits and risk assessment for welding/cutting

Occupational Health and Environmental Safety (EHS)

Our occupational health and safety framework supports worker well-being through dust suppression, noise control, clean drinking water, sanitation facilities, and proper waste management. These initiatives reflect our commitment to environmental health and safety (EHS) standards.

Dust Suppression

Regular water sprinkling to control airborne particles

Noise Control

Monitoring and control of noise levels within permissible limits

Water & Sanitation

Clean drinking water and proper sanitation facilities

Waste Management

Proper segregation and disposal of construction waste

Safety Training and Awareness Programs

Continuous learning is key to safety excellence. Regular toolbox talks, inductions, and construction safety training programs are conducted to educate workers on hazards, safe work methods, and emergency response procedures.

Toolbox Talks

Daily safety discussions before work commencement

New Worker Induction

Comprehensive safety orientation for all new personnel

Specialized Training

Certification programs for high-risk operations

Refresher Courses

Regular updates on safety procedures and regulations

Emergency Preparedness and Safety Compliance

All sites are equipped with first-aid facilities, trained responders, and clearly defined evacuation plans. Adherence to health and safety policy construction requirements ensures full safety compliance in the construction industry and readiness for emergencies.

First-Aid Facilities

Fully stocked medical kits and trained first-aiders

Emergency Response

24/7 emergency contact and response teams

Evacuation Plans

Clearly marked exits and regular evacuation drills

Compliance Documentation

Complete safety documentation and audit trails

Our Safety Pledge

At Nico Allen Infrastructure, safety is a shared responsibility and a core business value. By following robust safety measures in infrastructure projects, maintaining high safety standards, and continuously improving our systems, we strive to achieve a zero-accident workplace and deliver sustainable infrastructure solutions.

Safety & Compliance Topics

Commitment to Safety Excellence

At Nico Allen Infrastructure, we believe that safety is not just a policy but a way of life. Our commitment to protecting our people and the environment is unwavering.